Employee engagement in manufacturing is critical for company success. An engaged workforce is more productive, can deliver higher-quality work and employees are less likely to leave the company.

Unfortunately, employee engagement is low in the manufacturing industry. In a recent study, Gallup found that in 2024, the global percentage of engaged employees fell from 23% to 21%. In the manufacturing industry specifically, 26% of manufacturing leaders do not know if their frontline workers are engaged due to low participation in employee surveys or not carrying out an engagement survey.

On a positive note, there are many ways to engage manufacturing employees and drive greater retention across the workforce. In this blog, we’ll cover:

-

What is employee engagement in manufacturing?

-

Why is employee engagement in manufacturing important?

-

Reasons for poor employee engagement in manufacturing

-

How to improve employee engagement in manufacturing

Our goal is to provide tips and ideas to spark your imagination and get you on the right track to building and improving engagement for your manufacturing teams and deskless workforce.

Let's get straight into it!

What is employee engagement in manufacturing?

Employee engagement in manufacturing is the level of emotional commitment, motivation and connection employees feel towards their work, their team, and the organisation. It’s important to highlight that manufacturing work can be physically demanding. Employees lift, walk, or stand all day or night, depending on their shift, so maintaining their attention and keeping employees connected and engaged can be challenging for businesses.

The industry is constantly changing, with Deloitte’s 2025 Manufacturing Industry Outlook highlighting the industry’s primary challenge of a skilled staff shortage. Because manufacturing environments rely heavily on teamwork, accuracy and safety, engaged employees are more likely to stay focused, communicate clearly and contribute to a more productive workforce. In contrast, low engagement can lead to higher turnover, reduced productivity and even safety risks.

Why is employee engagement in manufacturing important?

Employee engagement directly impacts productivity, safety, quality and profitability in manufacturing. Engaged employees are more focused, committed and motivated to perform their work to the highest standard, reducing errors, maintaining safety protocols and contributing to a positive workplace culture.

Recommended reading 📚: 5 signs of positive workplace culture for employee retention

The cost of low engagement is substantial. Gallup estimates that disengaged employees cost U.S. businesses $450-550 billion each year. In contrast, research from Manufacturing Global shows that engaged manufacturing employees are 70% more productive than disengaged workers.

They also have a:

-

78% higher safety record

-

70% lower employee turnover

-

86% greater customer satisfaction

-

44% greater profitability

In an industry where precision, safety and efficiency are critical and skilled labour shortages are a growing challenge, building and maintaining engagement isn’t just a nice-to-have. It’s a competitive advantage and a core driver of business success.

Reasons for poor employee engagement in manufacturing

Low employee engagement in manufacturing often stems from three key challenges.

1. Lack of effective data and document management

Manufacturing involves complex procedures and strict compliance requirements that demand accurate, accessible information. Without a centralised system for storing training documentation, onboarding materials and safety policies, information can easily become lost or outdated. This not only disrupts workflow but also makes it harder for employees to stay engaged and informed.

A central, easy-to-use intranet can help overcome this barrier, especially in a workforce where not all employees are equally comfortable with new technology. Simplicity and accessibility are essential when employees are busy and have limited time to navigate complicated systems.

2. Outdated methods of communication

Many manufacturing companies still rely on outdated channels that fail to reach their entire workforce. Frontline employees on the factory floor, as well as those in logistics, procurement and other functions, need a reliable way to share updates and collaborate. An employee engagement app can act as a hub for the workforce, whilst an extranet can also support engaging external partners such as contractors.

With a multi-generational workforce, communication preferences vary widely. Without a unified platform that meets these needs, companies risk alienating parts of their workforce and weakening employee engagement.

Recommended reading 📚: Internal audiences: How to create them for IC (Free audience persona template)

3. Limited feedback opportunities

Employees who feel heard are far more likely to be engaged. According to research by UKG, employees with higher senses of belonging (95%) and engagement (92%) are significantly more likely to feel heard than those with lower belonging (25%) and engagement (30%).

Manufacturing leaders can address this by conducting regular surveys using anonymous pulse surveys and polls and most importantly, acting on feedback. This two-way communication creates trust, strengthens relationships and increases engagement.

How to improve employee engagement in manufacturing

Streamline communication channels 📲

In manufacturing, especially for frontline and deskless workers, communication must be simple, fast and accessible. Multiple disconnected channels make it harder for staff to find the information they need, which can lead to delays and frustration.

Best practice:

-

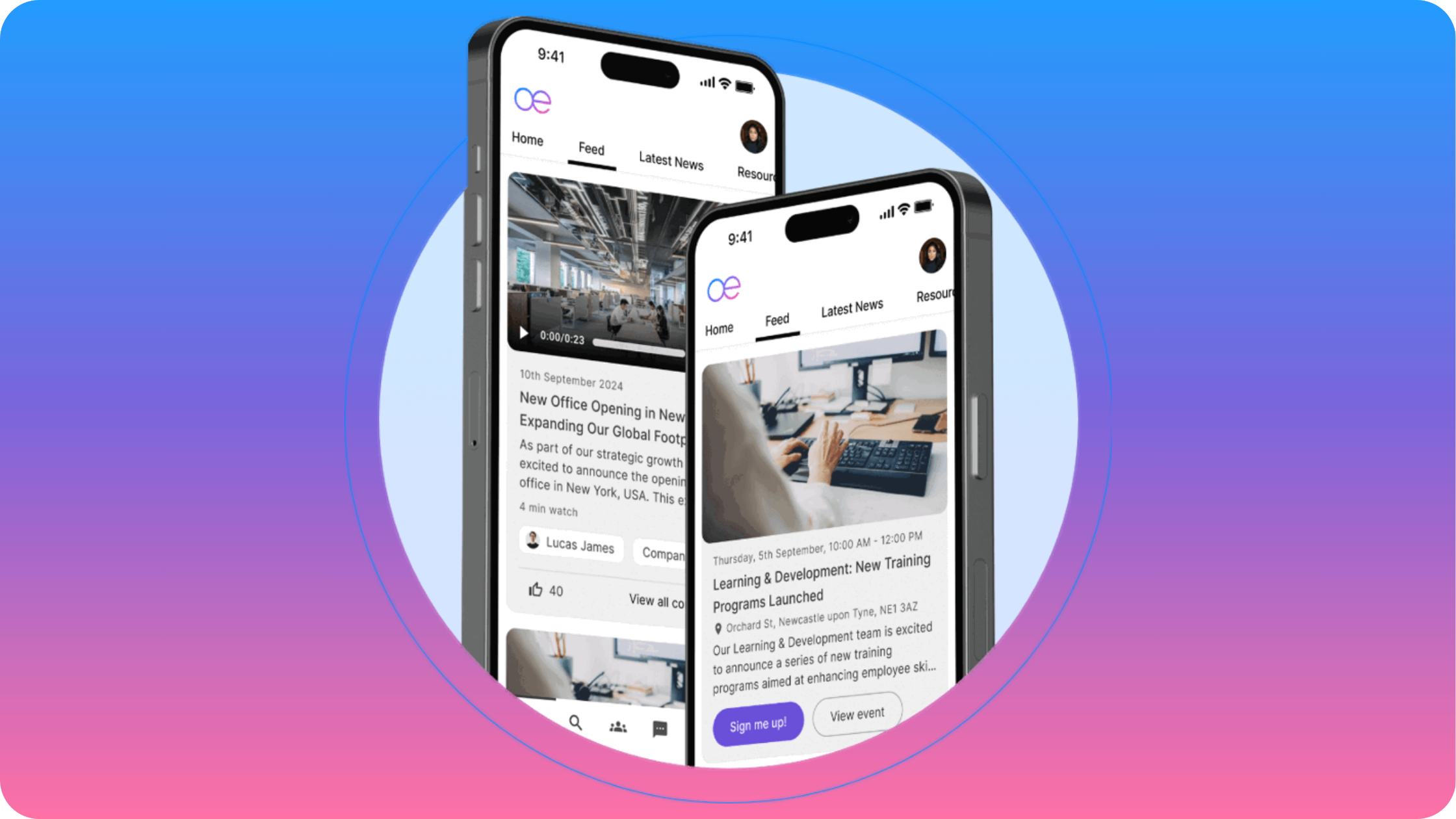

Consolidate tools into one central hub where employees can access shift updates, safety policies and company news in real time

-

Use mobile-friendly solutions so staff can stay connected from anywhere, regardless of shift pattern or location

Our intranet platform centralises communication and resources, allowing manufacturing teams to connect digitally even from the factory floor. This reduces delays, improves cross-department collaboration and ensures everyone stays informed.

Recognise and appreciate your employees 🌟

Workplace recognition is a vital contributor to employee engagement and happiness. A study of manufacturing workers showed that those who felt valued were more than four times as likely to report high levels of work engagement (59% vs. 13%).

Best practice:

-

Send a recognition message via your company intranet

-

Take 5 minutes at the end of a team meeting to give shout-outs

-

Provide regular and spontaneous verbal recognition

Gallup reports that well-recognised employees are 45% less likely to have turned over in the last two years. Yet, our employee happiness survey found that a third (33%) of people reported their place of work does not recognise employee achievements.

Offer a robust onboarding process 👋

Effective onboarding is a powerful way to improve employee engagement in manufacturing. A well-designed onboarding program reduces turnover and helps new hires feel part of the team from day one.

Best practice:

-

Begin with digital pre-boarding before their first day

-

Provide a personalised welcome page with key information like shift patterns, manager contact information and safety protocols

-

Introduce company resources to enable them to do their job more effectively

Burger King UK uses BK Hub for their personalised onboarding process which led to a 40% drop in new starter drop-outs within just six months.

Provide ongoing learning and development opportunities 📈

When employees understand how their work impacts the end product and have opportunities to grow, they’re more likely to stay motivated. It can also boost employee engagement in manufacturing by empowering workers to take control of their development.

Best practice:

-

Offer on-demand learning that fits around shifts

-

Access to a wide range of courses and resources for continuous learning

-

Upskill in specific areas like engineering, technology and digital manufacturing

According to a recent study, Rise Up found that 64% of employees state that learning and development has improved employee engagement in their organisations. Oak Engage integrates with existing LMS systems to help employees upskill and progress.

Send personalised news and updates 🤖

In the manufacturing industry, timing and clarity can mean the difference between smooth operations and costly mistakes.

Best practice:

-

Segment updates by role, location, or shift to ensure relevance

-

Share safety alters, stock updates and equipment notices only with the people who need them

-

Avoid information overload by curating content feeds

Oak Engage’s smart delivery functionality reduces information overload, increases engagement and ensures critical messages reach frontline workers promptly, even if they do not have regular email or desktop access.

Use push notifications for critical alerts 🔔

In manufacturing, quick, targeted communication can prevent costly downtime, improve safety and keep operations running smoothly. Push notifications are one of the fastest ways to reach the right people at the right time, directly on their mobile device or tablet.

Best practice:

-

Notify specific teams immediately in the event of equipment malfunctions, safety hazards or environmental risks

-

Send “mandatory read” notifications for new safety protocols, regulatory updates, or hazard alerts. Require confirmation to ensure compliance and accountability

-

Share delivery delays, supplier issues, or urgent customer requests to keep everyone aligned and responsive.

In busy factory environments, employees may not have constant access to email or desk-based systems. Push notifications cut through noise, ensuring urgent information is delivered in real time.

Enable two-way communication 📣

True employee engagement goes beyond delivering information. It’s about creating space for employees to respond, ask questions and share ideas. In manufacturing, where much of the workforce is on the frontline, giving people a voice can make them feel valued, heard and part of the bigger picture.

Best practice:

-

Feedback loops: Allow employees to reply directly to announcements with questions or comments

-

Pulse surveys and polls: Use short, targeted polls to gather opinions on process changes, shift scheduling, or workplace improvements.

-

Safe channels for reporting: Provide a safe and anonymous space for employees to leave feedback

Research by UKG shows that employees who feel heard are up to four times more engaged than those who don’t. Two-way communication also helps managers spot issues early, address misunderstandings quickly and build trust across the workforce.

Measure engagement with analytics 📈

Tracking how employees interact with communications, training and policies helps identify engagement gaps.

Best practice:

-

Monitor views, clicks and read rates for announcements, safety updates, and policy changes to ensure critical messages are getting through

-

Analyse survey responses over time to see if engagement is improving and where issues persist

-

Spot departments, sites, or shifts with high or low engagement levels and tailor strategies to each group

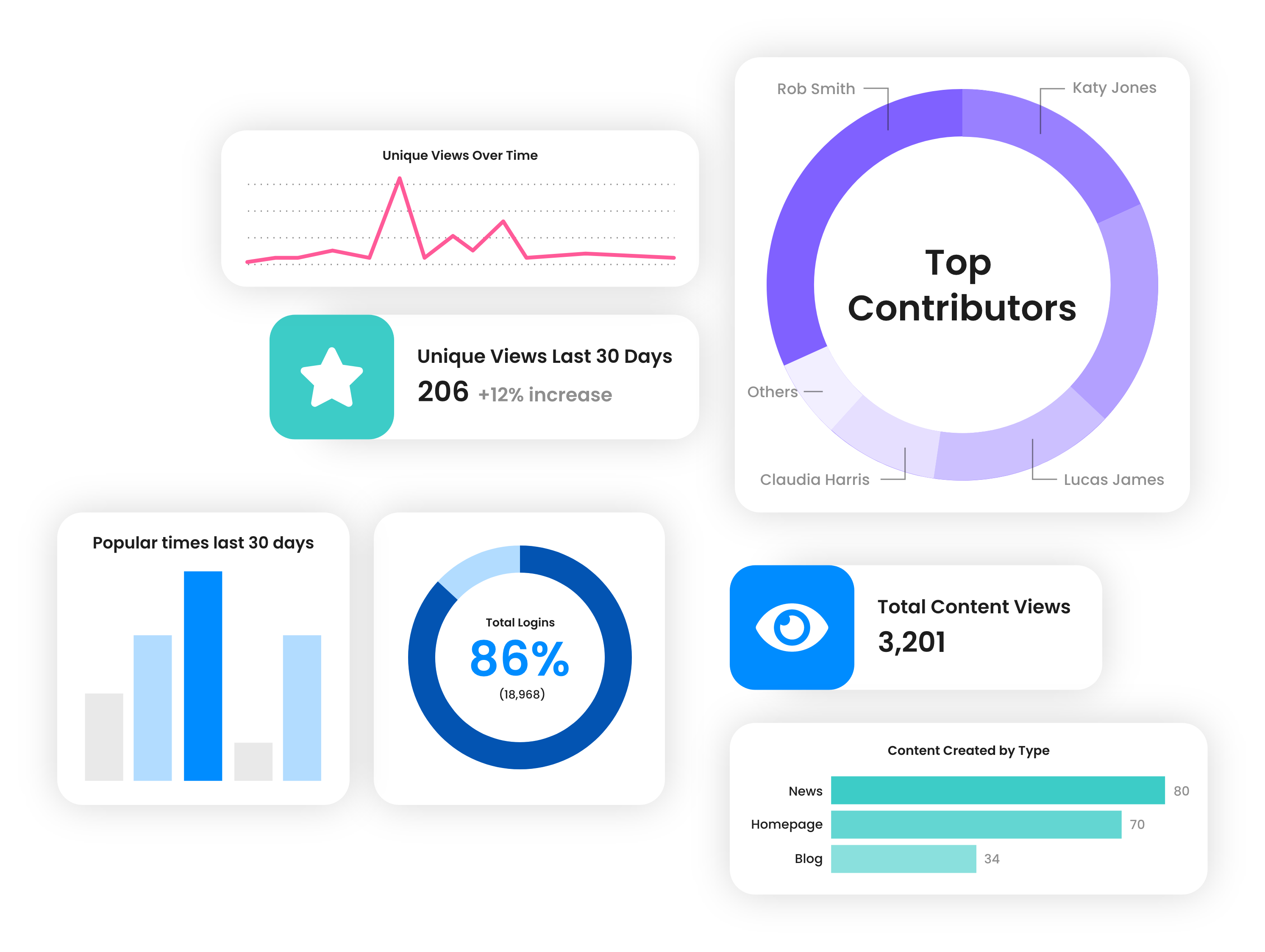

Oak’s intranet analytics dashboard shows which updates are read, which safety documents are acknowledged and where employee engagement in manufacturing can be improved, helping leaders make informed decisions.

Empower your manufacturing teams to stay engaged and connected

Building strong employee engagement in manufacturing can lead to significant improvements in motivation and productivity across the workforce. It also reduces turnover, improves morale and strengthens customer service. By creating open lines of communication, recognising contributions and supporting ongoing development, manufacturing organisations can build a more engaged and loyal workforce.

A modern intranet or employee app such as Oak Engage can be the backbone of this strategy, keeping teams connected no matter where or when they work. Check out our deskless workers guide for more practical tips.